Checking Out Core Boring Equipment: Vital Devices for Precision in Geotechnical Investigations

Core exploration equipment plays an essential function in geotechnical examinations. These specialized devices enable designers to extract accurate samples from diverse geological formations. Understanding the different elements, such as drill gears and core little bits, is vital for effective sampling. As modern technology advancements, so too do the techniques made use of in core exploration. The implications of these growths on security and accuracy increase essential questions regarding their application in real-world tasks. What difficulties stay in enhancing these devices?

Overview of Core Boring Devices

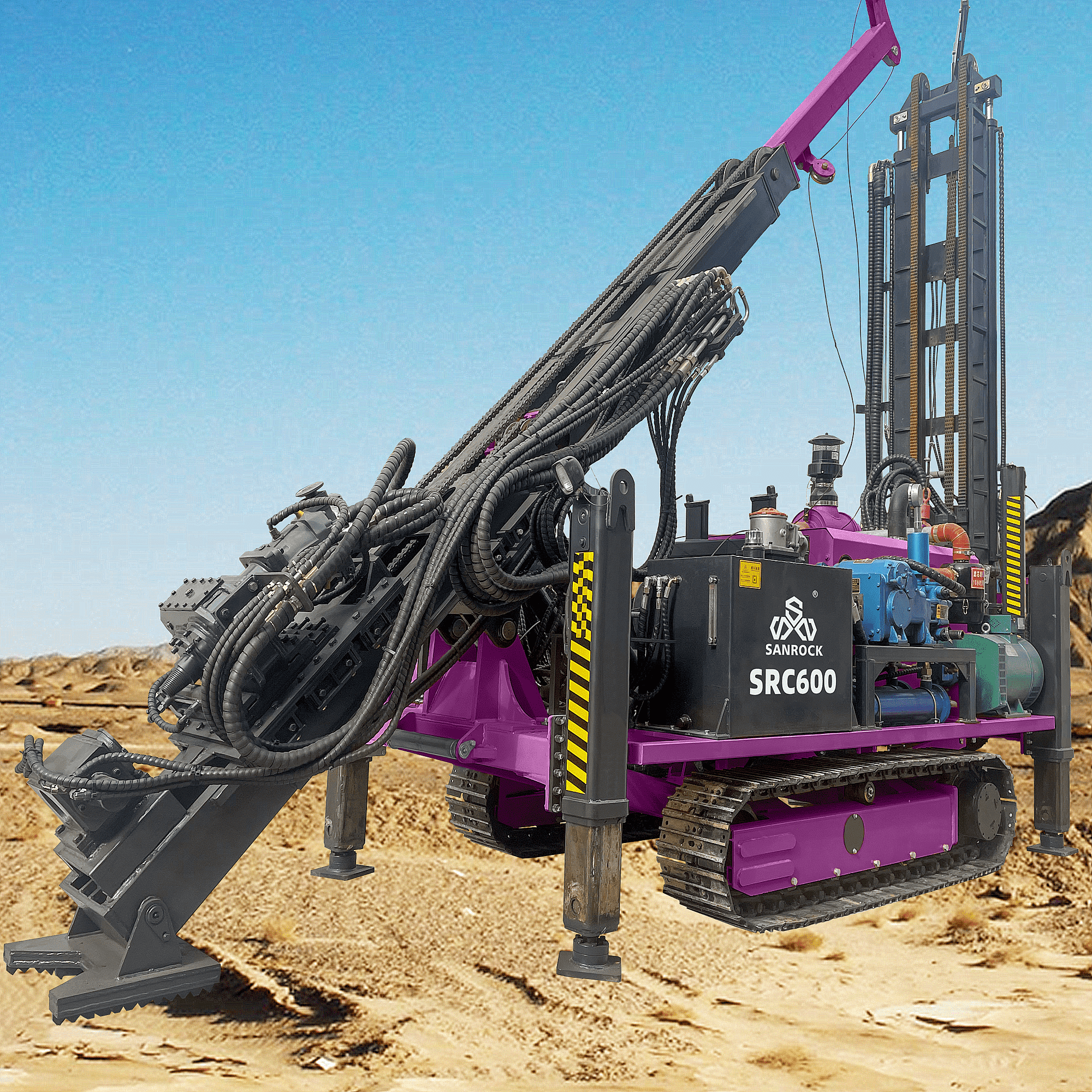

Core drilling equipment is essential for removing round samples from different geological developments. This equipment commonly consists of a drill gear, diamond or carbide-tipped drill bits, and core barrels developed to preserve the tested product. The drill gear gives the required power and stability for the boring procedure, frequently featuring hydraulic systems that enable efficient penetration into hard rock or dirt. Pierce little bits are engineered to stand up to extreme stress and abrasion, guaranteeing reliable puncturing various materials. Core barrels play a crucial function in protecting the integrity and recording of the samples, permitting exact geological analysis. The devices is commonly installed on cars or trailers for wheelchair, allowing access to remote places. Additionally, developments in modern technology have actually resulted in the advancement of automatic and portable core drilling systems, enhancing operational effectiveness and safety. Generally, core drilling devices is indispensable for rock hounds and engineers in their pursuit to recognize subsurface conditions.

Sorts Of Core Drilling Rigs

Core exploration gears can be found in different kinds, each made for certain applications and geological conditions. Rotary exploration gears, ruby core drills, and wireline core systems represent the primary classifications made use of in the industry. Recognizing the qualities and benefits of each gear kind is crucial for effective core tasting and geological exploration.

Rotary Drilling Gears

When discovering the various kinds of core drilling rigs, rotating drilling rigs attract attention because of their effectiveness and flexibility in drawing out geological examples. These gears use a revolving drill little bit that cuts through rock and dirt, making them suitable for a wide variety of applications, including mineral exploration and ecological assessments. Rotating boring gears can be categorized right into different kinds, such as truck-mounted, trailer-mounted, and portable devices, each created for specific surfaces and functional demands. The gears typically use a drilling liquid to cool down the little bit and lug drill cuttings to the surface, boosting the general drilling procedure. Their durable style and versatility make rotary exploration rigs a favored selection in geotechnical investigations, helping with dependable and specific sample collection.

Diamond Core Drills

Diamond core drills represent a specialized classification of drilling devices made for high-precision geological tasting. These drills utilize diamond-impregnated little bits, enabling them to reduce via hard rock formations with exceptional efficiency. The key advantage of ruby core boring lies in its capacity to create constant core samples, which are essential for geological analysis and mineral expedition. Offered in various sizes and setups, ruby core drills can be adapted for different depths and geological problems. They are commonly mounted on portable gears, making them flexible for field applications. The precision of diamond core boring not just boosts the quality of accumulated examples but additionally minimizes the risk of contamination, thereby guaranteeing trusted data for geotechnical examinations.

Wireline Core Solutions

Wireline core systems represent a cutting-edge improvement in core boring modern technology, permitting efficient retrieval of core samples from substantial depths. These systems make use of a wireline strategy that makes it possible for the continual removal of core examples without the requirement to continuously draw the whole drill string from the borehole. This capability considerably decreases downtime and enhances operational effectiveness. Wireline core systems are especially beneficial in challenging geological problems, as they reduce disruption to the borehole and protect sample honesty. Different kinds of wireline core gears exist, tailored for particular geological settings and task needs. Their flexibility and efficiency make wireline core systems a favored choice in modern-day geotechnical investigations, ensuring accurate data collection for design and ecological analyses.

Necessary Core Little Bits and Their Applications

Core little bits work as vital devices in the field of boring, allowing the removal of cylindrical samples from various geological formations. These little bits are created to penetrate different materials, consisting of soil, concrete, and rock, each with certain applications tailored to the geological context. For example, diamond core little bits are favored for their toughness and effectiveness when puncturing tough rock, making them perfect for mineral exploration and geotechnical analyses. Conversely, carbide-tipped core bits are frequently made use of for softer developments, supplying a cost-efficient service for getting examples in less challenging atmospheres. In addition, specialized core bits, such as those geared up for environmental exploration, warranty very little disruption to the surrounding location, which is necessary in contamination analysis projects. The choice of core little bit straight affects the top quality of the examples accumulated, consequently affecting subsequent analyses and decision-making in engineering and ecological evaluations.

Developments in Core Boring Innovation

Recent developments in core boring innovation have considerably enhanced the performance and efficiency of geological sampling. Advanced exploration rigs currently include automation and remote monitoring capacities, permitting operators to collect data in real-time while decreasing human treatment - Core Drilling Equipment. These innovations result in boosted precision and faster completion of boring tasks

In addition, the development of high-performance diamond core bits has changed the infiltration capabilities of drilling equipment, making it possible for much deeper and extra challenging geological developments to be experienced easily. New layers and materials utilized in little bit manufacturing enhance durability and lower wear, substantially prolonging the life-span of core boring devices.

The integration of computer-aided layout (CAD) software program allows for specific planning and implementation of Continue boring procedures, making it less complicated to adjust to differing geological problems. In general, these technical improvements not just improve the core drilling process but additionally supply geotechnical professionals with vital data for informed decision-making.

Security Considerations in Core Exploration Workflow

Safety factors to consider in core drilling procedures are critical to making certain the health of workers and the integrity of the job. Appropriate training for operators is vital, as it furnishes them with the essential skills to take care of equipment safely and recognize prospective hazards. Individual safety equipment (PPE) such as headgears, handwear covers, and eye protection should be put on to reduce threats connected with flying debris and heavy machinery.

Additionally, regular safety audits and danger evaluations need to be performed to determine and attend to any type of possible dangers on-site. Guaranteeing that tools is effectively hop over to these guys protected and kept can prevent accidents associated to tools failing. When boring in confined spaces to avoid direct exposure to hazardous gases, sufficient air flow is also crucial. In addition, developing clear communication protocols amongst group members promotes a safer working setting. Eventually, fostering a culture of security is crucial for the effective execution of core exploration operations.

Maintaining and Servicing Core Drilling Devices

Servicing and maintaining core boring tools is vital for guaranteeing peak performance and expanding the life expectancy of the machinery. Normal inspections must be performed to identify wear and tear on crucial parts such as drill little bits, motors, and hydraulic systems - Core Drilling Equipment. Appropriate cleaning after each usage helps get rid of debris and avoids corrosion, which can significantly influence performance. Lubrication of moving components is important to minimize rubbing and prevent overheating, while likewise enhancing functional performance

Set up maintenance regimens, consisting of changing used components and examining fluid levels, must be purely followed. Operators needs to likewise be educated to identify indications of breakdown, making it possible for timely repair services and decreasing downtime. Maintaining extensive service documents help in tracking the devices's track record and forecasting future maintenance needs. Overall, aggressive maintenance not only protects the integrity of core boring tools however additionally adds to more secure and more accurate geotechnical examinations.

Case Researches: Effective Applications of Core Exploration in Geotechnical Projects

Core drilling has shown vital in various geotechnical tasks, specifically in framework development and ecological analysis studies. Instance research studies illustrate just how this technique promotes the collection of vital subsurface information, educating task planning and implementation. These effective applications highlight the flexibility and performance of core boring in attending to complicated geotechnical obstacles.

Framework Growth Projects

Exactly how do effective facilities advancement tasks take advantage of core boring to improve geotechnical evaluations? Core boring acts as a crucial device in examining subsurface problems, enabling designers to obtain trusted soil and rock samples. Such analyses are significant for figuring out the suitability of sites for numerous infrastructures, including tunnels, bridges, and freeways. Notable study illustrate how core drilling has been used in large-scale jobs, such as the building of urban transit systems. In these instances, core samples supplied important data on dirt structure and groundwater levels, helping with informed decision-making pertaining to foundation layout and product selection. The assimilation of core drilling right into facilities development not only improves task timelines however likewise minimizes dangers linked with unforeseen subsurface difficulties.

Ecological Analysis Studies

While examining ecological influences is vital for lasting advancement, the application of core drilling in geotechnical jobs has actually proven to be vital. Core drilling allows the collection of subsurface examples, giving important data on soil composition, groundwater levels, and pollutant existence. Numerous instance studies illustrate its performance in assessing prospective ecological dangers prior to construction starts. As an example, in a seaside advancement project, core samples determined high degrees of salinity in the dirt, triggering modifications to the initial design to minimize future erosion risks. Similarly, in urban areas, core drilling has contributed in identifying buried contaminants, ensuring that removal efforts are properly straightened with task goals. These applications highlight core drilling's function in fostering informed decision-making and advertising ecological stewardship.

Frequently Asked Inquiries

Exactly how Do I Pick the Right Core Drilling Devices for My Job?

To select the ideal core exploration equipment, one should think about task requirements, dirt kinds, deepness needs, and budget plan restrictions. Consulting with specialists and assessing devices efficiency ratings can likewise offer beneficial insights for informed decision-making.

What Are the Prices Related To Core Exploration Equipment Rental?

Costs connected with core exploration devices rental generally differ based on equipment duration, area, and kind. Normally, costs vary from $100 to $1,000 each day, with additional fees for try this out distribution, upkeep, and needed devices.

Can Core Drilling Devices Be Used in Different Dirt Types?

Core exploration tools can be properly used throughout various soil kinds, including rock, clay, and sand. Its versatility permits for precise tasting and analysis, making it a valuable device in varied geotechnical environments and applications.

What Is the Ordinary Life Expectancy of Core Boring Equipment?

The ordinary life-span of core drilling devices commonly varies from 10 to two decades, depending upon aspects such as maintenance methods, usage frequency, and the problems in which the devices is run throughout drilling jobs.

Exactly How Do Environmental Problems Influence Core Boring Procedures?

Environmental problems significantly influence core exploration procedures. Aspects such as dirt dampness, temperature level fluctuations, and weather patterns can influence equipment performance, drilling speed, and the top quality of samples obtained, eventually affecting job results and timelines.

Rotary drilling rigs, ruby core drills, and wireline core systems represent the key categories utilized in the sector. When checking out the numerous kinds of core exploration gears, rotating drilling rigs stand out due to their effectiveness and flexibility in removing geological examples. The key benefit of diamond core exploration lies in its capability to create continual core examples, which are crucial for geological analysis and mineral exploration. Wireline core systems represent an ingenious advancement in core exploration innovation, allowing for efficient retrieval of core examples from significant depths. Costs linked with core boring devices rental usually differ based on devices period, type, and place.